Material:Chrome

Content:10%-28%

Usage:Construction,Machinery,chemical,Petroleum,Grind,Refractory Material,Cement Plant,Mining Mill

Processing Type:Casting

Size:8*10-40*45mm

Color:Black

production Description

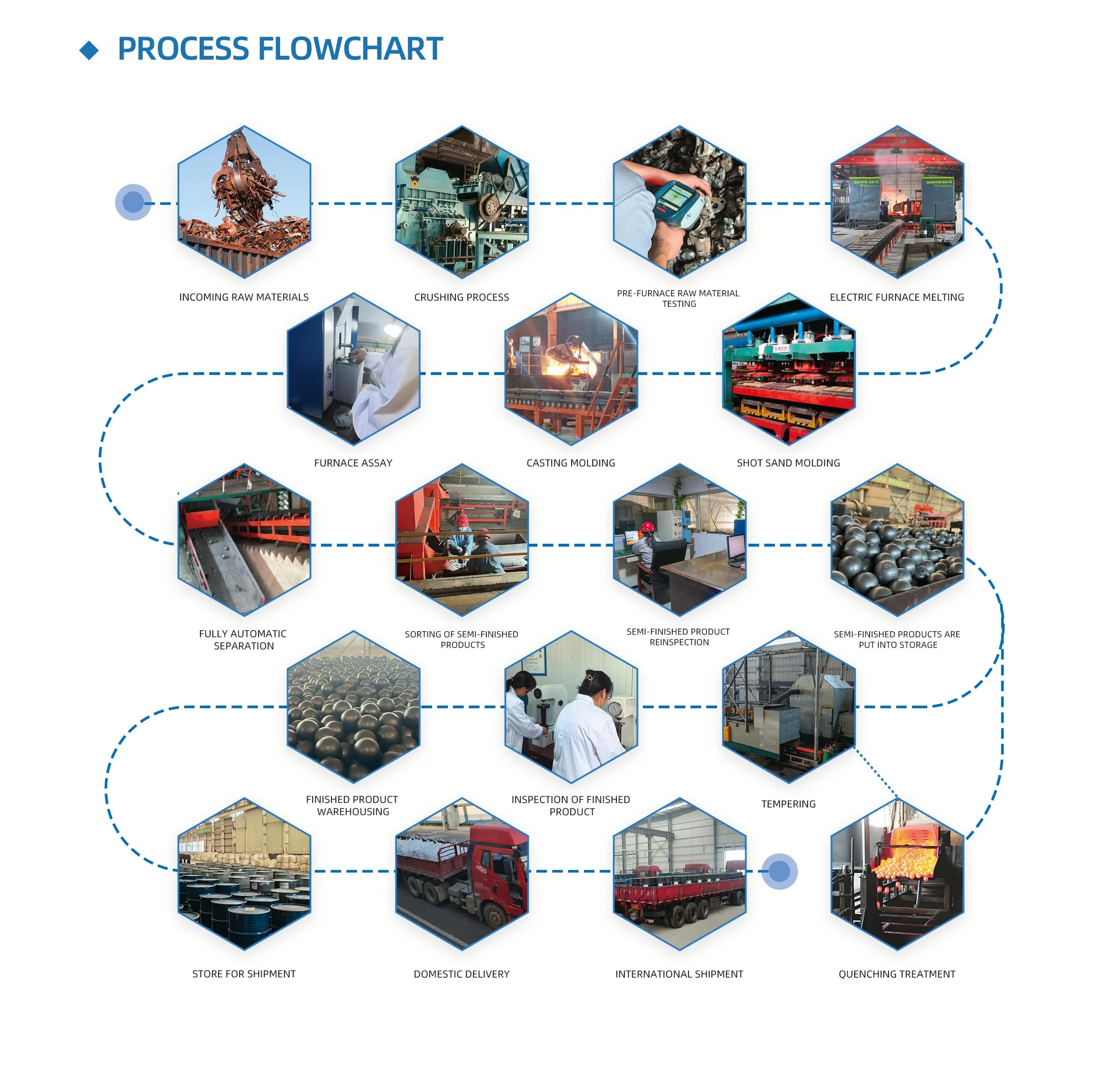

High chromium wear-resistant steel forging is a kind of chromium white cast iron. The production process of high chromium wear-resistant steel forging includes melting high-quality scrap steel, chromium alloy and other alloy materials, and then through micro-alloying treatment, tempering, and finally using sand casting. After high temperature quenching and tempering treatment, martensitic matrix can be obtained, thus achieving high hardness and wear resistance.

High chromium wear-resistant steel forging is widely used in industrial fields, especially in the powder preparation and ultra-fine deep processing in cement, mining, coal slurry thermal power and other industries, which improves the grinding efficiency, reduces the shutdown time and the number of times of opening and shutting down, extends the clearance cycle, and reduces the labor intensity of workers. At the same time, it is of great significance to increase the output of the mill, ensure the quality of the abrasive, and reduce the power consumption and the consumption of the grinding body.

Grinding media information | |||

Model NO. | High chromium grinding forging | Customized | Customized |

Hardness | 58-63HRC | Heat Treatment | Oil Quenching |

Broken Rate | <0.5% | Moder No. | Zqcr10 |

Transport Package | Durm or Bag | Specification | High Chrome Grinding Media |

Trademark | Chengda | Origin | China |

HS Code | 7325910000 | Production Capacity | 60000 Tons |

Designation | Chemical Compositions(%) | ||||||

C | Si | Mn | Cr | Mo | P | S | |

ZDCr26 | 2.2-3.0 | ≤1.0 | 0.3-1.0 | 24.0-30.0 | ≤1.0 | ≤0.10 | ≤0.06 |

ZDCr23 | 2.2-3.0 | ≤1.0 | 0.3-1.0 | 22.0-24.0 | ≤1.1 | ≤0.10 | ≤0.06 |

ZDCr20 | 2.2-3.0 | ≤1.0 | 0.3-1.0 | 18.0-22.0 | ≤1.0 | ≤0.10 | ≤0.06 |

ZDCr17 | 2.2-3.0 | ≤1.0 | 0.3-1.0 | 16.0-18.0 | ≤1.0 | ≤0.10 | ≤0.06 |

ZDCr15 | 2.2-3.0 | ≤1.0 | 0.3-1.0 | 14.0-16.0 | ≤1.1 | ≤0.10 | ≤0.06 |

ZDCr12 | 2.2-3.0 | ≤1.0 | 0.3-1.0 | 10.0-14.0 | ≤1.0 | ≤0.10 | ≤0.06 |

ZDCr8 | 2.2-3.2 | ≤1.0 | 0.3-1.5 | 7.0-10.0 | ≤1.0 | ≤0.10 | ≤0.06 |

ZDCr5 | 2.2-3.2 | ≤1.0 | 0.3-1.5 | 4.0-6.0 | ≤1.0 | ≤0.10 | ≤0.10 |

ZDCr2 | 2.2-3.2 | ≤1.0 | 0.3-1.5 | 1.3-3.5 | ≤1.0 | ≤0.10 | ≤0.10 |

ZDCADI | 3.3-3.9 | 2.4-3.0 | 2.4-2.9 | 0.2-0.5 | ≤0.5 | ≤0.06 | ≤0.05 |

Designation | Surface HRC | Core HRC | Microstucture |

ZDCr28 | ≥62 | ≥62 | M+C |

ZDCr26 | ≥62 | ≥62 | M+C |

ZDCr23 | ≥62 | ≥62 | M+C |

ZDCr20 | ≥62 | ≥62 | M+C |

ZDCr17 | ≥62 | ≥62 | M+C |

ZDCr15 | ≥62 | ≥62 | M+C |

ZDCr12 | ≥62 | ≥62 | M+C |

ZDCr8 | 50-55 | 50-55 | P+C/M+C |

ZDCr5 | 50-55 | 50-55 | P+C/M+C |

ZDCr2 | ≥48 | ≥47 | P+C |

ZDCADI | 55-60 | 55-60 | B+Fe |

C-Carbide M-Martensite A-Ferrite B-Bainit Fe-Ferrite | |||

Specification (mm) | Weight of Each Ball (Kg) | Pcs/ton |

φ8×10 | 0.0039 | 255056 |

φ10×12 | 0.0074 | 136030 |

φ12×14 | 0.0120 | 80970 |

φ14×16 | 0.0190 | 52052 |

φ16×18 | 0.0280 | 35424 |

φ18×20 | 0.0400 | 25191 |

φ20×25 | 0.0610 | 16324 |

φ25×30 | 0.1150 | 8706 |

φ30×35 | 0.1930 | 5182 |

φ35×40 | 0.3000 | 3331 |

φ40×45 | 0.4400 | 2267 |

φ45×55 | 0.5711 | 1751 |

φ55×60 | 0.8611 | 1161 |

Excellent wear resistance: The chemical composition of the high chromium alloy wear layer has a high carbon content, and the chromium content is as high as about 30%, the volume fraction of Cr7C3 carbide in the metallographic structure reaches more than 50%, and the macroscopic surface hardness is HRC56~62, which makes its wear resistance significantly improved.

Good impact resistance: the substrate is low carbon steel or low alloy steel and other ductile materials, wear-resistant layer combined with the substrate, showing good impact resistance, suitable for bearing high drop hopper and other impact and wear material handling system.

Good corrosion resistance: Because the alloy layer contains a high percentage of chromium metal, it has a certain rust and corrosion resistance, which is suitable for the occasions of easy adhesion materials